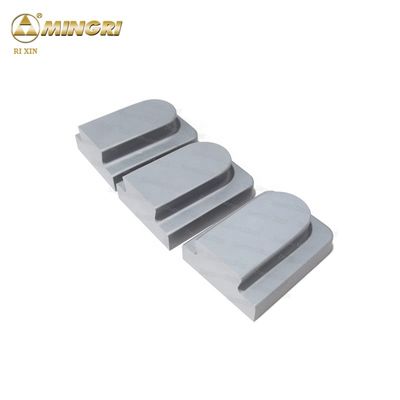

YG11C YG15 YG15C Tungsten Carbide Edge Block for HPGR Roller Press Studded Wear Parts

Подробная информация о продукте:

| Место происхождения: | Хунань, Китай |

| Фирменное наименование: | Rixin |

| Номер модели: | Шпилька из карбида вольфрама-3 |

Оплата и доставка Условия:

| Количество мин заказа: | 1 |

|---|---|

| Цена: | $59 |

|

Подробная информация |

|||

| Материал: | Карбид вольфрама | Обработка поверхности: | Завершить заземление |

|---|---|---|---|

| Размер: | Индивидуальные | Трс: | > 3000 Н/мм3 |

| Твердость: | 85-92 ХРА | Служба срока службы: | 10000 - 30000 часов |

| Оценка: | YG11C, YG15, YG15C, YG18, YG20 | Поверхность: | Полированный |

| Источник питания: | Электрический | Тип двигателя: | Электрический |

| Ударопрочность: | Высокий | Плотность: | Высокий |

| Износостойкость: | Высокий | Индивидуальная поддержка: | OEM |

| Производительность: | Высокая твердость, прочность | ||

| Выделить: | YG11C Tungsten Carbide Edge Block,YG15 HPGR Edge Block,YG15C Hard Metal Edge Block |

||

Характер продукции

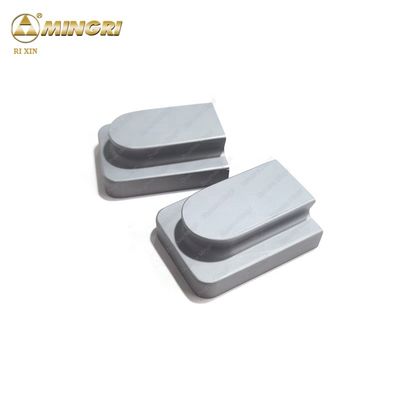

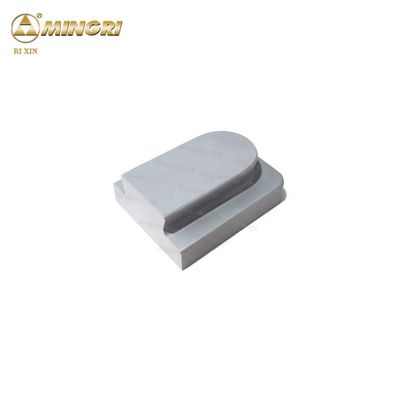

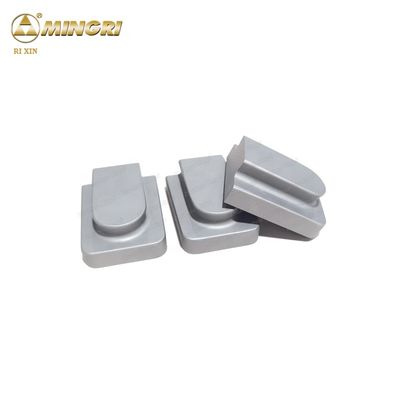

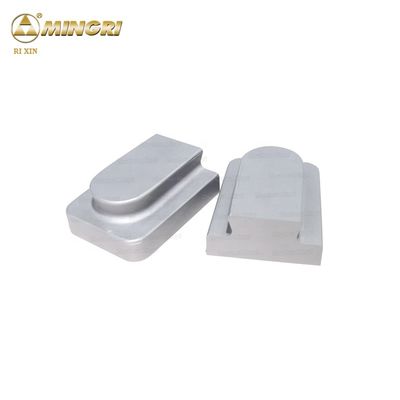

Tungsten Carbide Hard Metal Edge Block OEM Polished for HPGR Roller Press Studded Wear Parts Iron Ore Crushing

Hard Metal Edge Block for HPGR Roller Press Studded Wear Parts

| Item | Tungsten carbide edge block |

|---|---|

| Grade | YG11C, YG15, YG15C, YG18, YG20 |

| Sizes | Standard or customized |

| Brand | Rixin |

| Country of Origin | Zhuzhou, China |

| Usage | High pressure grinding roller, iron ore, cement crushing |

Tungsten carbide edge blocks are widely used on the rollers of High Pressure Grinding Roll. With excellent properties of high hardness, strength and impact resistance, these components significantly improve the service life and work efficiency of HPGR machines. Compared to traditional hardfacing rollers, tungsten carbide edge blocks offer up to 10 times longer service life.

Grade and Usage Specifications

Available Sizes and Types

Packaging and Delivery

Our Product Range

We specialize in manufacturing various tungsten carbide profiles and dies, cutting tools, mining tools, wear parts, and customized tool parts with superior performance for industrial applications.

Manufacturing Capabilities

Our facilities include powder mixing, pressing, sintering, finishing, surface treatment, and mold design workshops, along with physical and chemical labs for quality inspection. With hundreds of updated equipment, we maintain a monthly production capacity of 50 tons while ensuring excellent quality standards.

Quality Assurance

All products undergo strict ultrasonic inspection before shipment, ensuring no defects such as pores. Our tungsten carbide components feature high density, exceptional wear and impact resistance, resulting in significantly extended service life.

Our Team and Industry Presence

Contact Information

Хотите узнать больше подробностей об этом продукте